Endless Improvements

العربية

Heat Transfer Fluids

Most productive systems, in many of the industrial sectors, at some stage of their process require heating, either from intermediate components or final product, with this heating being also one of the basic, if not critical, points of the system.

Thermal fluid heating systems are indirect heat transfer systems that control temperature conditions by circulating a thermal fluid throughout the equipment. This process allows for fine-tuned heating using a single thermal transfer fluid.

1. Heat Transfer Fluid Circuit:

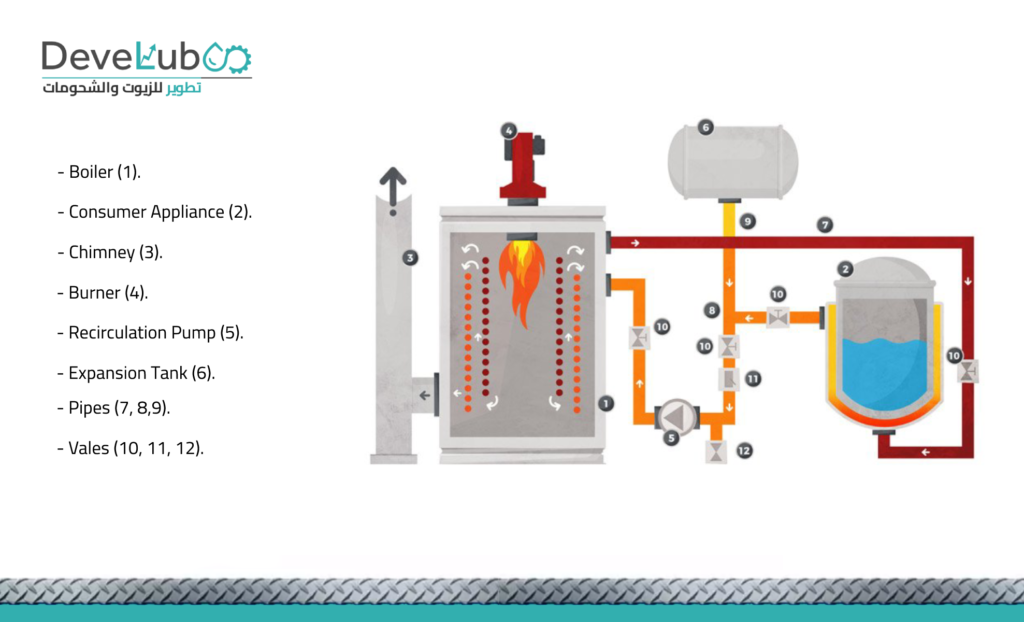

In the basic diagram.

A boiler (1), to which a burner (4) is fitted and which has a flue or chimney (3) to eliminate combustion gases, heats the heat transfer fluid, which, by means of pipes (7, 8, 9), reaches the consumer appliance (2), where the energy is given out and it then returns to the boiler, closing the cycle.

To properly complete the heat transfer fluid circuit, we have two basic elements:

The recirculation pump (5) and the expansion tank (6). The expansion tank is connected to the system using a pipe, known as a compensation pipe, which allows us to send the increased volume produced by heating the whole circuit to the tank. and, in the cooling or end of day phase, to compensate for the lower level produced due to an increase in the fluid’s density upon cooling.

The final items that can be added are the small basic extras, such as: fittings (10, 11, 12)that allow us to isolate any appliance or consumer from the system, both for maintenance as well as safety purposes.

2. Heat Transfer Fluids Characteristics:

A heat transfer fluid must possess specific characteristics to be able to carry out its function of transporting energy with technical proficiency and at a moderate cost.

a. Thermal Stability – Maximum Operating Temperature:

Thermal stability is defined simply as the ability of a heat transfer fluid to withstand the molecular cracking of the thermal stress. The relative thermal stability test for heat transfer fluids measures the molecular bond strength of a fluid at a specific temperature compared to another fluid at the same temperature and under identical test conditions. The tests are carried out under ideal laboratory conditions and do not take into account operational stresses such as mechanical failures, design defects, oxidation, etc. and, therefore, the data generated are only useful for comparative purposes. The exact predictions for the life of the fluid in actual processes should not be taken from the thermal stability data.

The maximum operating temperature is the maximum temperature recommended by the fluid manufacturer at which it can be used in continuous use while still maintaining an acceptable level of thermal stability.

Most mineral oils have a maximum recommended temperature of between 270°C and 315°C.

Synthetic or aromatic oils have a maximum recommended temperatures of between 315°C and 400°C.

Because the degradation rates of the fluid are closely linked to the temperature, habitually working above the maximum operating temperature of the fluid will exponentially increase the degradation rate. Potential problems caused by excessive degradation and the subsequent formation of degradation by-products include increased coking and dirt, mechanical difficulties and a decrease in heat transfer efficiency.

b. Heat Transfer Efficiency:

Comparisons of heat transfer efficiency between different heat transfer fluids are made using heat transfer coefficients. At a specific temperature, the overall heat transfer coefficient of a fluid can be calculated at a given flow rate and pipe diameter using its:

Viscosity.

Density.

Thermal Conductivity.

Specific Heat.

When assessing this property, it should be noted that greater efficiency in heat transfer does not, in most cases, represent an economic saving in fuel (which basically depends on the design of the boiler) as may initially appear, but this property will result in less time in obtaining the energy objectives of our process. Thus, with equal exchangeable surfaces in our consuming apparatus, we will reach the required operating temperature faster if the heat transfer fluid has a high heat transfer efficiency.

Most synthetic thermal fluids have a significant advantage over mineral oils in heat transfer efficiency at temperatures between 150°C and 260°C. Above this temperature range (up to 300°C), some mineral heat transfer fluids narrow the gap with highly refined paraffinic / naphthenic white oils.

c. Minimum Pumping Temperature:

The temperature at which the viscosity of the fluid reaches a value, typically 2000 cps, at which centrifugal pumps cannot circulate the fluid.

Although most process applications are run at temperatures well above this point, system designs may encounter problems during emergency shutdowns or maintenance shutdowns if we have not taken this requirement into account in the acquisition of our system’s heat transfer fluid.

Most mineral heat transfer oils and mid-range synthetic fluids have start-up values in the range of -20ºC to -5ºC.

High-end synthetic fluids – aromatic synthetic fluids with biphenyl / diphenyl oxide and with maximum operating temperatures of (370°C : 400°C), have values of 5°C – 15°C as their minimum pumping temperatures.

3. Heat Transfer Fluids Degradation:

Heat transfer fluids degrade over time due to thermal cracking and oxidation. The degradation speed can be influenced by inadequate operating procedures, bad design or contamination.

The equipment must be designed to be properly sealed, either by the so-called “hydraulic cushion” method or by other systems, including the use of inert gases. Check that whatever system used in the equipment design works correctly, with enough hydraulic cushion and the proper nitrogen pressure.

The design should also ensure that the temperature in the expansion tank is kept below 70°C. Do not insulate the expansion tank or the pipes connected to it.

Perform maintenance operations with the fluid at temperatures below 60°C.

Replace mechanical pump seals and gaskets only if leaks are detected. Whenever the equipment stops, the entry of air may be facilitated by a vacuum occurring at those points.

Before any modification or expansion of the equipment, it must be re-commissioned by repeating the initial dehydration process.

Oxidation

Heat transfer fluids react with air to form organic acids. The oxidation rate is low at ambient conditions but increases rapidly with temperature. These acids can be subjected to the polymerization of free radicals that increase the viscosity of the fluid and, ultimately, give rise to sludge deposits.

Because the degradation rates of the fluid are closely linked to the temperature, habitually working above the maximum operating temperature of the fluid will exponentially increase the degradation rate. Potential problems caused by excessive degradation and the subsequent formation of degradation by-products include increased coking and dirt, mechanical difficulties and a decrease in heat transfer efficiency.

Thermal Cracking

Thermal cracking is a decomposition of a thermal fluid into high and low boiling point components, due to exceeding the maximum recommended thermal fluid film temperature.

Low boiling point components: consist of the most volatile factions in the fluid, which evaporate and are eliminated to the outside by the expansion tanks. This causes non-uniform warming and pump cavitation.

High boiling point components: composed of thermal fluid substances which are carbonized and adhere to the walls of the coils.

Thermal cracking decreases the boiler performance as these products become pseudo-insulators with the increase in fuel that this represents with the obvious production difficulties.

As the fluid degrades, a smaller amount of heat passes through the coil pipes and the temperature of the wall increases. This burns out and destroys the coils and the boiler has to be replaced.

4. Used Oil Analysis

There are three main parameters:

a. Acid Number:

This measures the amount of acid present in the liquid from the mass (in milligrams) of potassium hydroxide (KOH) required to neutralize one gram of the sample; this indicates the amount of oxidation that has occurred. The higher the acid number, the more oxidation will have occurred.

Sludge deposits and a high viscosity are symptoms of oxidation and are the most common reasons for fluid degradation. However, unless there is water present, these acids are not corrosive in the traditional sense.

Most oxidation products are soluble in the thermal fluid and reactions take place between them, forming sludge, especially at points where sedimentation is favorable; for example, in the expansion tank, as previously indicated. However, other oxidation products are insoluble and can lead to deposits, partial clogging of pipes and accelerated mechanical deterioration of seals, valves and pumps, for example.

Boundary Values:

| Value | Status | Observations |

| < 0.05 | Excellent. | New fluid. |

| > 0.3 | Symptoms of oxidation. | Continue to be used in normal operation. |

| > 0.6 | Oxidation take place. | More frequent fluid analysis – Review equipment design and sealing. |

| > 0.9 | End of fluid life. | Immediate change of the fluid. |

Facebook Comments