Endless Improvements

العربية

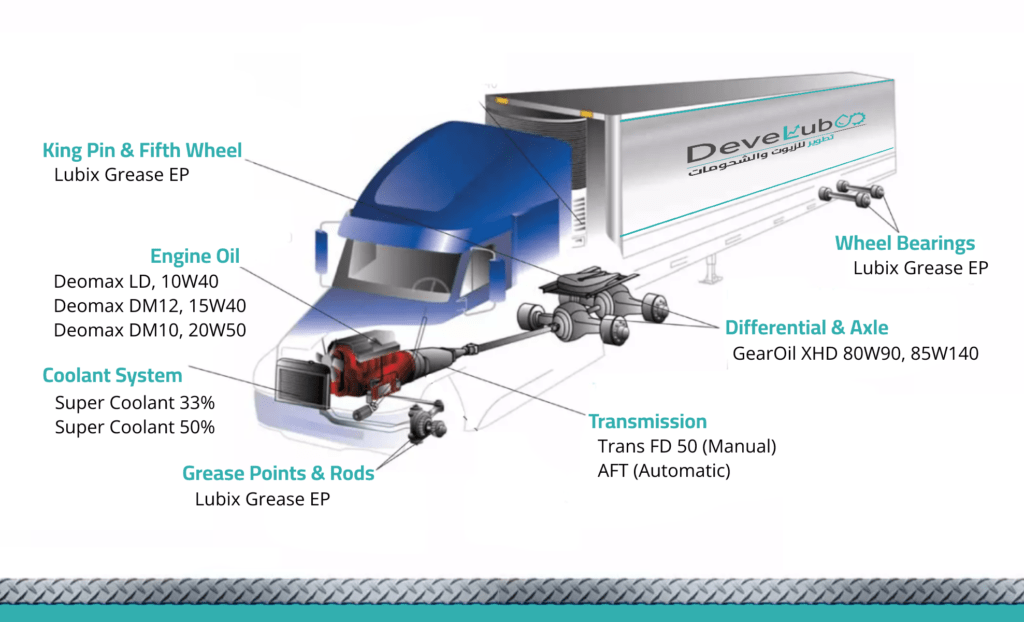

On-highway Vehicle

DeveLub customers need to keep their fleet running well and hence; they need a partner who able to offer a complete solution that keeps their fleet running efficiently over a long haul. DeveLub offers a full range of premium quality Automotive Lubricants.

OLA Energy products 0ffer:

Leave a Reply