Endless Improvements

العربية

Who is DeveLub?

DeveLub Technical Program –

People Preparedness

Full package training for:

○ Managers.

○ Engineers.

○ Technicians.

○ Warehouse keepers.

Machine Preparedness

Machine proper state of:

○ Inspection.

○ Contamination control.

○ Oil sampling instruments.

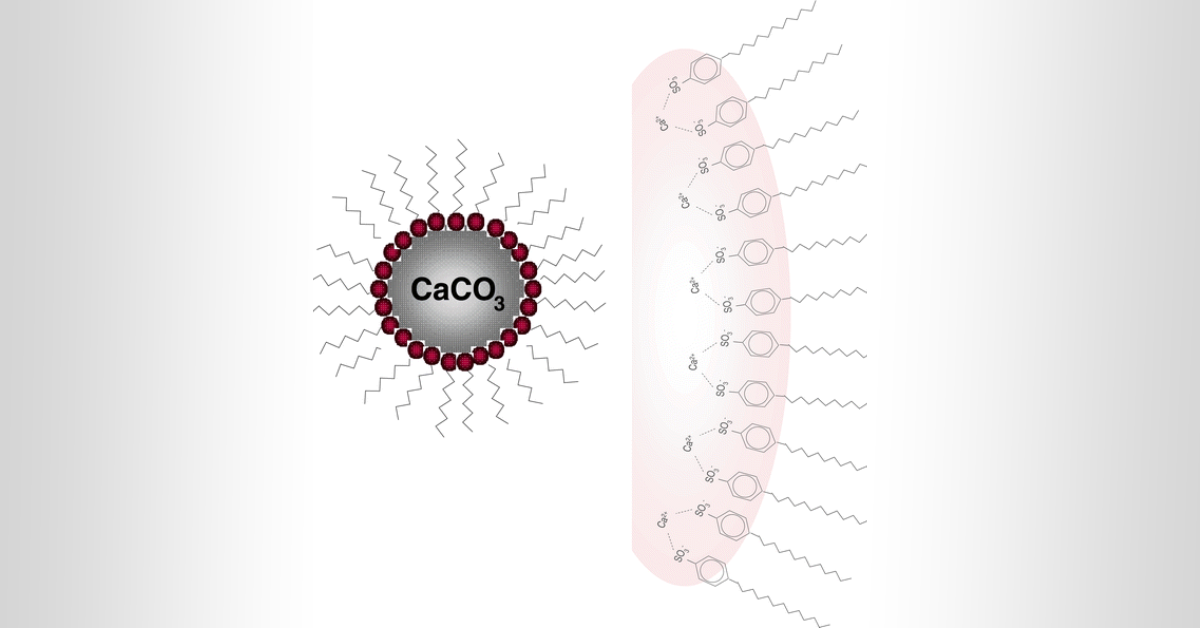

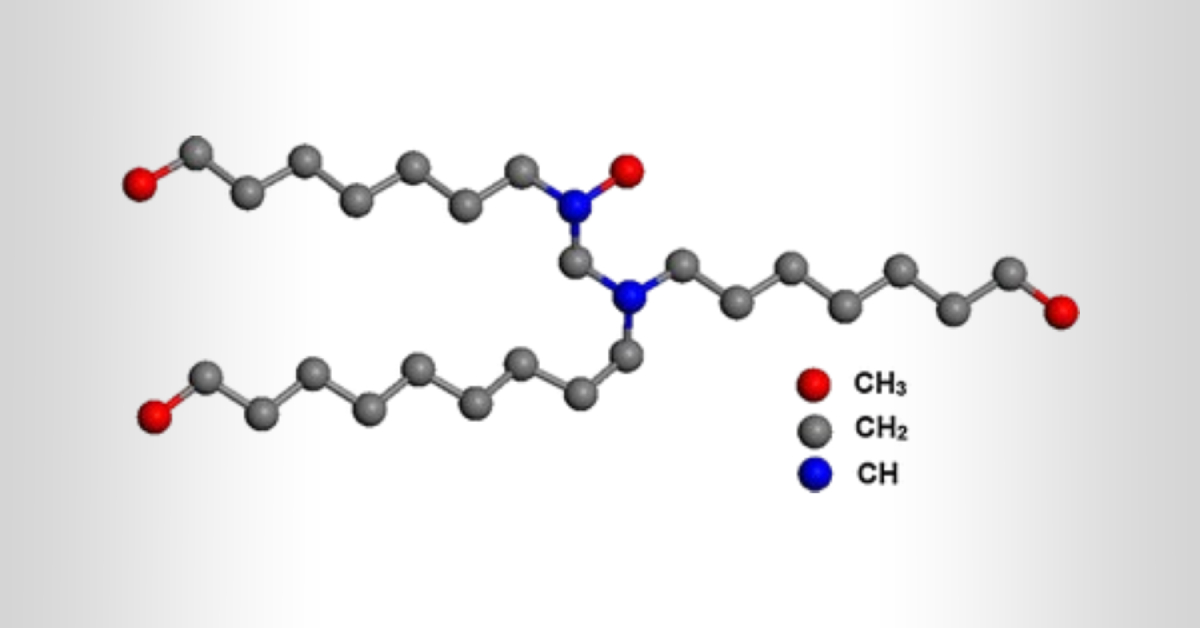

Precision Lubricants

Select the proper lubricants:

○ Base oil.

○ Additives.

○ Thickeners.

Precision Lubrication

Proper lubrication process:

○ Procedure.

○ Frequency.

○ Amount.

○ Locations.

Oil Analysis

Effective program:

○ Test slate.

○ Frequency.

○ Alarms.

On-highway Vehicle

DeveLub customers need to keep their fleet running well and hence; they need a partner who able to offer a complete solution that keeps their efficiently.

Read More

Construction Equipment

Construction equipment must run reliably despite harsh conditions.

Operators need a partner that ables to maximize productivity and minimize maintenance cost.

Read More

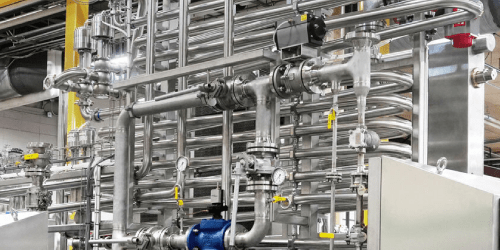

Heat Transfer Fluids

Thermal fluid heating systems are control temp. by circulating fluid throughout the equipment. Fluid must be carefully chosen to accommodate the requirements.

Read More

Industrial Gear Lubricants

Industrial Gear oils are lubricants designed to protect gears, bearings, and seals in all types of enclosed gear drive with circulation or splash lubrication systems.

Read More

Recent Posts

-

February 11, 2024

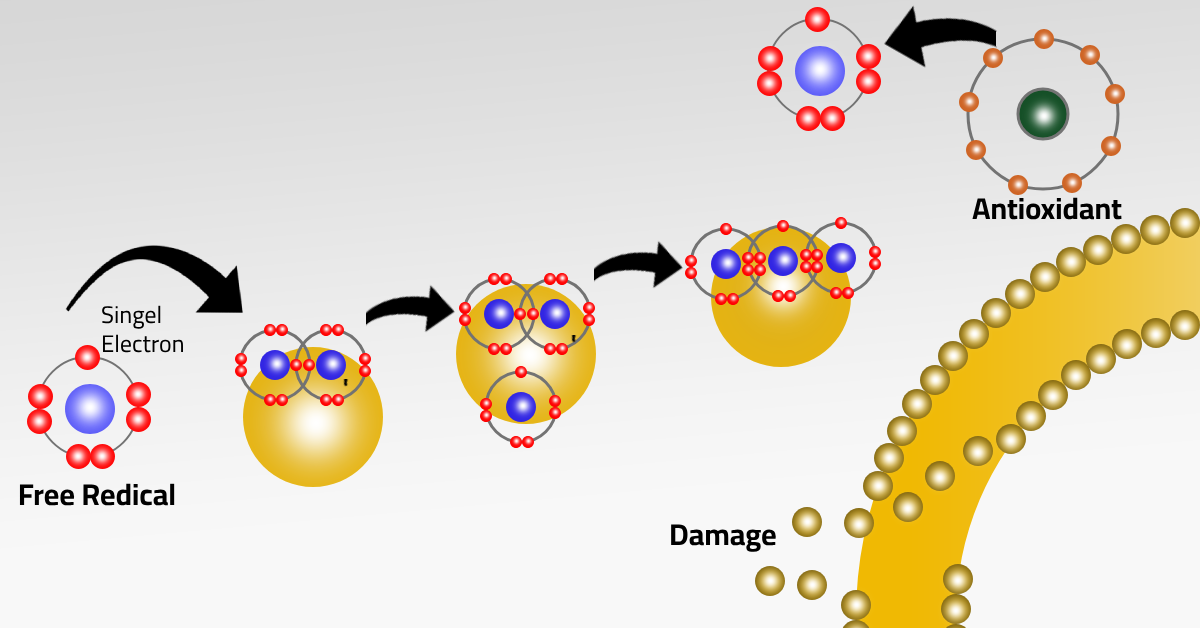

Read more: Additives – AntioxidantsFor the prevention of lubricant oxidation, antioxidants are the key additive that protects the lubricant from oxidative degradation

-

January 28, 2024

Read more: Polyalphaolefin Base OilPolyalphaolefin is by far the most common major synthetic base oil used in industrial and automotive lubricants.

-

January 21, 2024

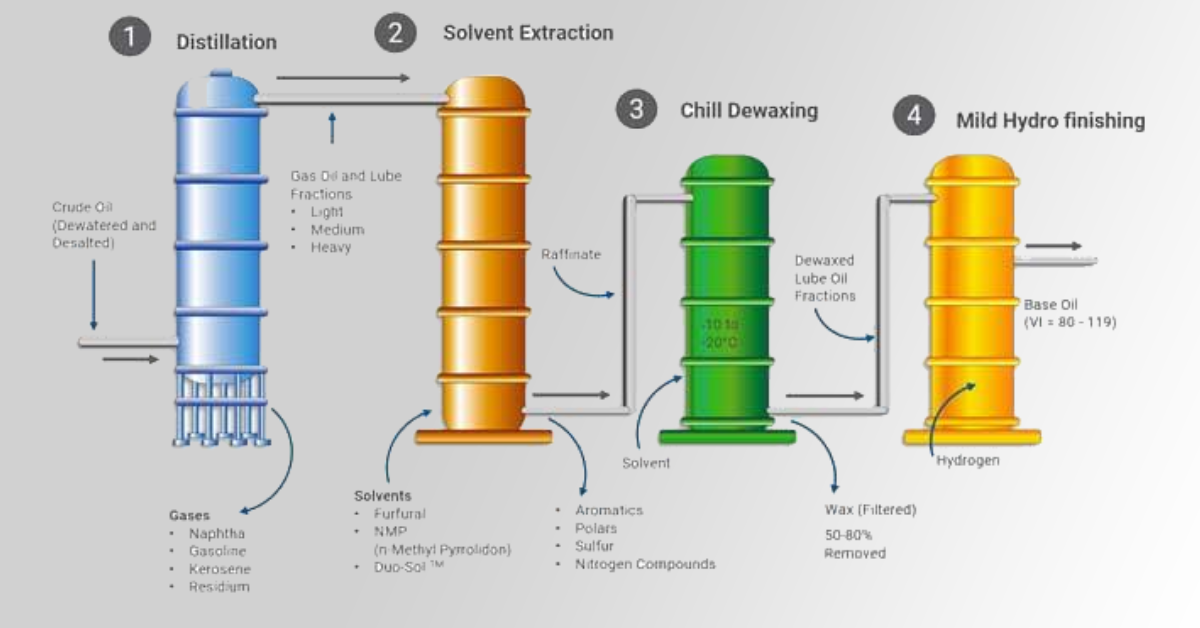

Read more: Mineral Base Oil ManufacturingMineral Base Oil Manufacturing by distillation of petroleum then removing some of the less desirable components.

-

March 10, 2024

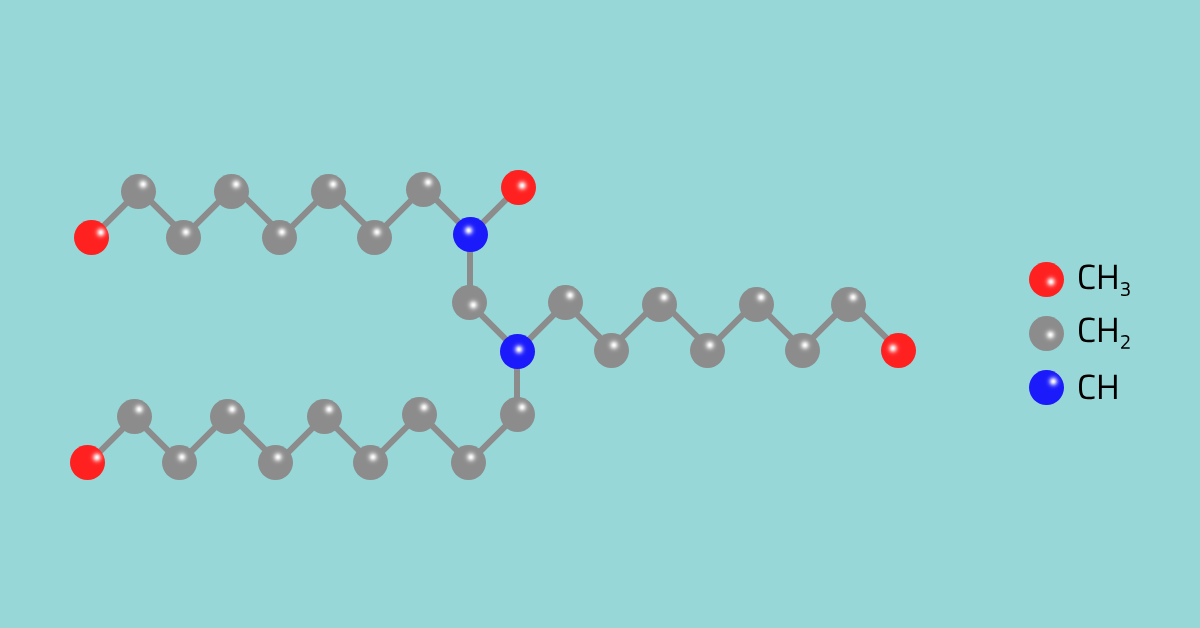

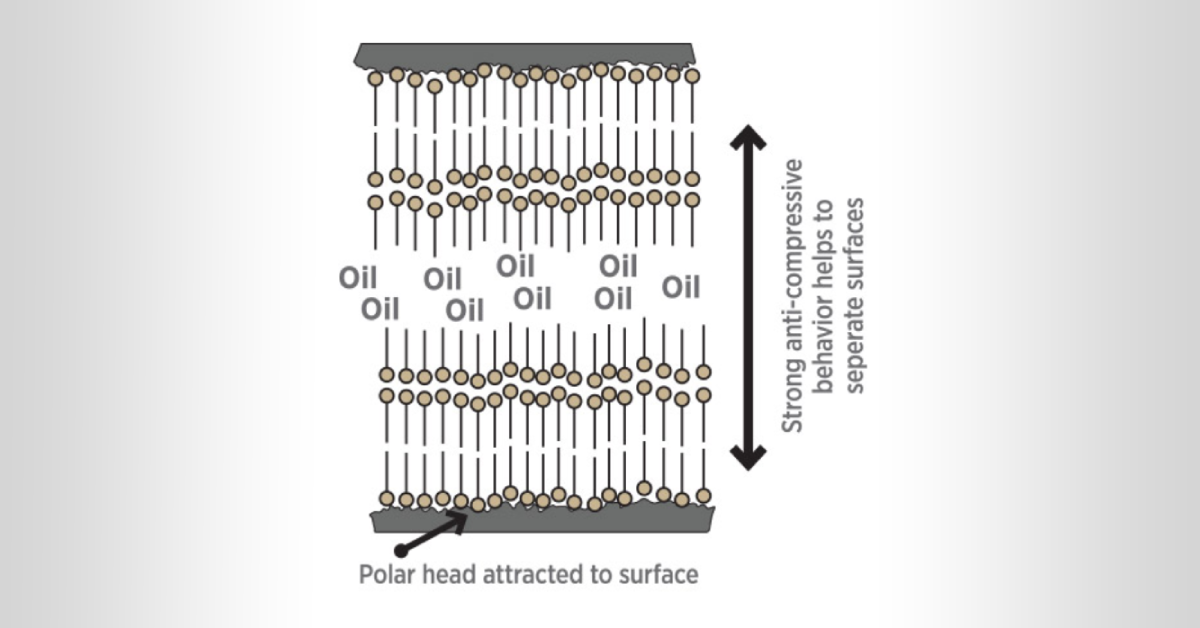

Read more: Organic Friction ModifiersOil made use of friction modifiers to meet requirements for smooth transition from static to dynamic condition as well as reduced noise, frictional heat, and startup torque.

-

March 3, 2024

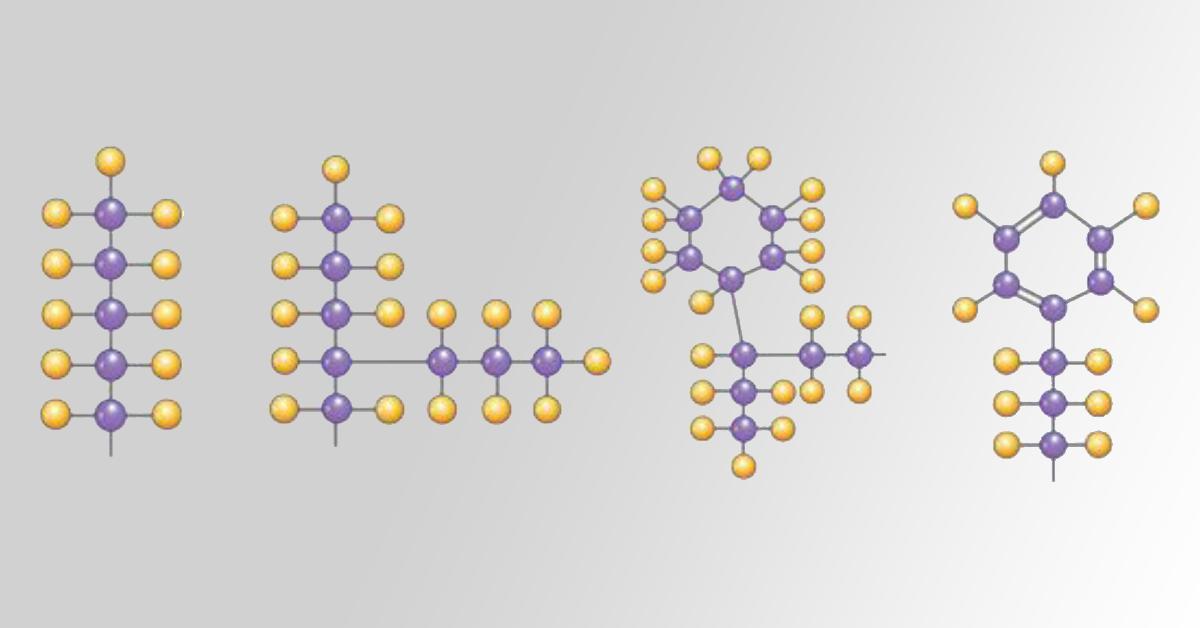

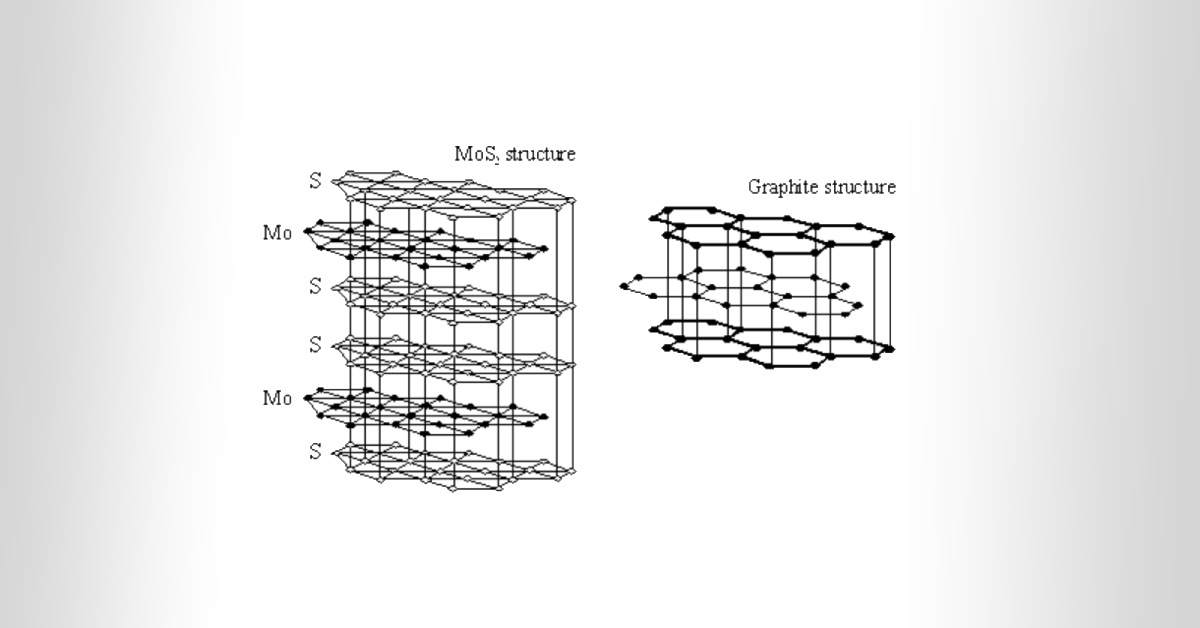

Read more: Solid Lubricants as Friction ModifiersSolid lubricants are any solid material that reduces friction and mechanical interactions between surfaces in relative motion.

-

February 25, 2024

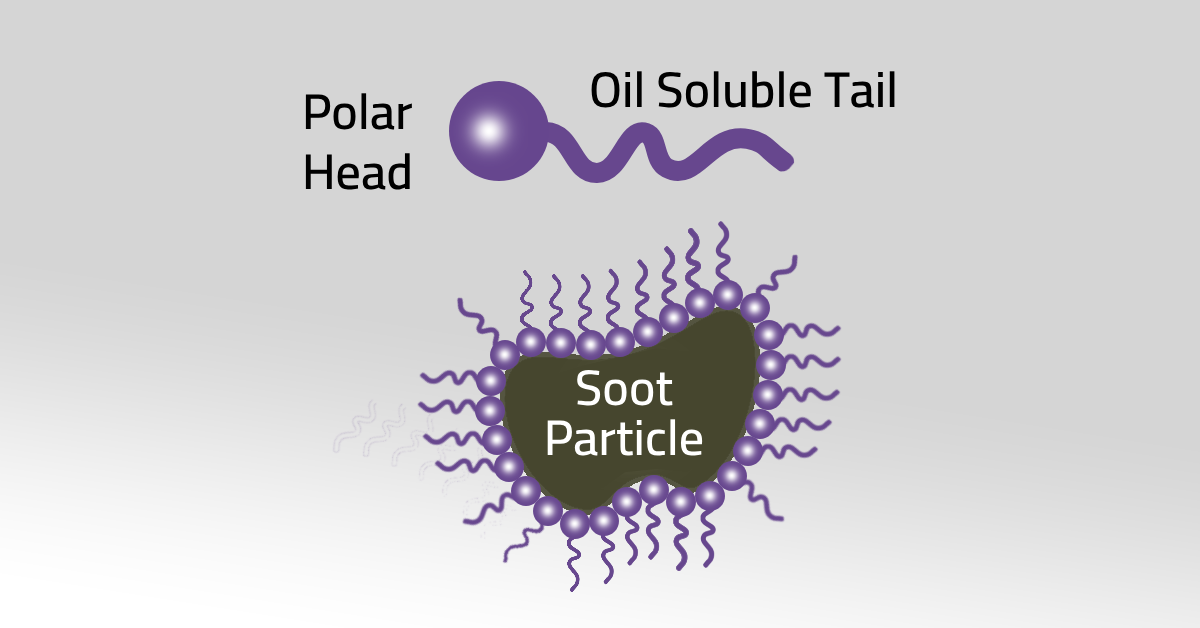

Read more: Additives – DispersantsDispersing soot and deposits is clearly the primary function of a dispersant. Dispersants need other properties to perform effectively.

Recent Videos

High Temp. Corrosion Bench Test

Determining the tendency of diesel engine lubricants to corrode the alloys of lead and copper commonly used in cam followers and bearings.

Read More

Foam Bench Test

Evaluating the foaming characteristics of diesel engine oils. The tendency of oils to foam can lead to mechanical failure.

Read More